In the world of nonwoven fabrics, two of the most commonly used manufacturing methods are the wet laid and dry laid nonwoven processes. If you’re a buyer, product developer, or simply researching fabric technologies, understanding these two processes is essential for selecting the right material for your needs. This article will explore the differences between wet laid and dry laid nonwoven technologies, their advantages, applications, and how to choose between them.

What Is Dry Laid Nonwoven Process?

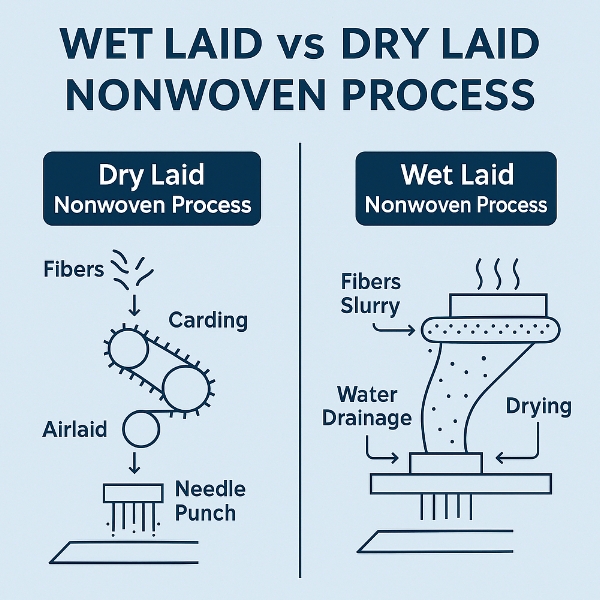

The dry laid nonwoven process is a technique where loose fibers are first opened, carded, and then laid onto a conveyor belt to form a web. This web is then bonded using thermal, chemical, or mechanical methods to create a finished nonwoven fabric.

Key Features of Dry Laid Nonwoven:

- Uses natural fibers, synthetic fibers, or blends

- Web formed using air (airlaid) or carding machines

- Bonding options: needle punching, chemical bonding, or hot calendaring

- Ideal for light to medium-weight fabrics

Applications:

- Medical textiles (surgical tape backing, face mask layers)

- Filtration materials

- Household cleaning cloths

- Personal hygiene products

What Is Wet Laid Nonwoven Process?

The wet laid nonwoven process is similar to traditional papermaking. Fibers are dispersed in water to form a slurry and then deposited onto a moving screen. Water is drained off, and the resulting web is bonded and dried to create a uniform nonwoven fabric.

Key Features of Wet Laid Nonwoven:

- High uniformity and flatness

- Suitable for short fibers (e.g., <10 mm)

- Typically bonded by chemical or thermal methods

- Commonly uses cellulose, glass fibers, polyester, or synthetic pulp

Applications:

- Battery separators

- Medical packaging and tapes

- Label base materials

- Industrial filtration media

- Wallpaper backing and specialty papers

Wet Laid vs Dry Laid: Key Differences

| Feature | Dry Laid Nonwoven | Wet Laid Nonwoven |

|---|---|---|

| Web formation | Mechanically or air-laid | Fiber slurry in water |

| Fiber length | Medium to long fibers | Short fibers (<10mm) |

| Fabric uniformity | Good | Excellent |

| Production similarity | Textile industry | Paper industry |

| Common bonding | Needle punch, thermal, chemical | Chemical, thermal |

| Applications | Hygiene, wipes, filters | Battery, tapes, packaging |

How to Choose the Right Nonwoven Technology?

Choosing between wetlaid and dry laid nonwoven fabric depends on:

- End Use – Wet laid is ideal for ultra-smooth, high-uniformity materials (e.g., battery separators or paper-like nonwovens), while dry laid suits applications that require strength or absorbency.

- Required Fiber Type – If your material involves short fibers or needs paper-like properties, wet laid is often better.

- Budget & Volume – Wet laid equipment is typically higher in cost and best for large-scale production.

Looking for a Wet Laid or Dry Laid Nonwoven Manufacturer?

At NW Fabric, we specialize in custom nonwoven fabric manufacturing using both dry laid and wet laid technologies. Whether you need nonwoven materials for medical, industrial, filtration, or packaging applications, we can support you with:

- High-quality materials

- Flexible GSM ranges

- Customized bonding and finishes

- Technical support and sampling

👉 Contact us today to request a sample or learn more about our nonwoven manufacturing capabilities.

Conclusion

Understanding the differences between the wet laid and dry laid nonwoven processes can help you make informed decisions about materials for your next product or project. Each process offers unique advantages, and the right choice depends on your performance requirements, cost, and end-use. If you’re seeking a trusted partner in nonwoven manufacturing, NW Fabric is here to help.