Description

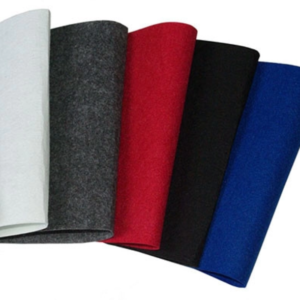

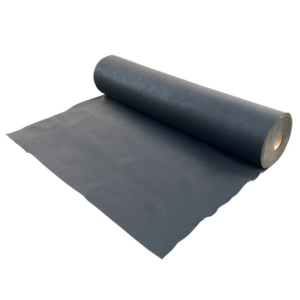

This Super Absorpt Lint-Free Needle Punched Nonwoven Fabric is made from Viscose Polyester, a degradable and breathable material, making it an eco-friendly choice for household and industrial applications.

1. Hero Section

- Multi-Purpose Use: Suitable for various uses, including home textile, agriculture, industry, and outdoor activities, this nonwoven fabric can be used as a cleaning wipe cloth for kitchens, furniture, or as a gardening tool.

- Customizable Options: Available in a range of widths (0.2-3.4m or 47/48″), weights (90-150g or 350/500g), colors (green or customized), and thicknesses (1-6mm or medium weight), allowing users to tailor the product to their specific needs.

- Effective Cleaning: The needle-punched nonwoven technics and water-resistant properties make this fabric an ideal choice for cleaning and wiping surfaces, providing a durable and effective cleaning experience.

2. Core Material Properties

Technical Specifications

| Parameter | Specifications |

|---|---|

| Fiber Composition | PET/PP/Viscose/Custom Blends |

| GSM Range | 90-500 g/m² (±3% tolerance) |

| Thickness | 1-6.0 mm (adjustable needling density) |

| Roll Dimensions | 1000-3200mm width × 100-500m length |

| Tensile Strength | 28-40N/5cm (MD/CD) |

| Oil Absorption | 200-280% (ASTM D5802) |

3. Manufacturing Capabilities

Production Advantages:

✓ 6-Stage Vertical Needling with Dilo Hyperpunch Systems

✓ Real-time GSM Monitoring via Mahlo γ-ray Sensors (±1.5g/m² accuracy)

✓ In-house Fiber Blending (CV ≤0.8%)

✓ Dual Quality Control: Pre-needling fiber mat & post-production testing

Equipment List:

- Autefa Solutions Crosslapper

- Dilo Hyperpunch® 4.0 Needle Loom

- Mahlo Omniscan GSM Monitoring System

4. Application Engineering Support

Optimal Material Selection Guide:

| Application | Recommended Specs |

|---|---|

| Industrial Wipes | 500-800gsm PET/PP Blend (High Abrasion Resistance) |

| Precision Cleaning | 180-300gsm Fine Denier Fibers (Low Lint Generation) |

| Medical-grade | OEKO-TEX® Certified PP (Sterilizable) |

Value-added Services:

- Free Sample Rolls (10 linear meters)

- Needling Pattern Optimization

- Lamination/Coating Technical Consultation

5. Competitive Advantages

| Parameter | Industry Standard | Our Fabric |

|---|---|---|

| GSM Consistency | ±5% | ±2.5% |

| MOQ | 5 MT | 1 MT |

| Custom Development | 8-10 weeks | 4-6 weeks |

| Roll Seam Quality | Thermal Bonded | Ultrasonic Welding |

6. Compliance & Certification

- ISO 9073 Series Test Reports

- REACH SVHC Compliance Documentation

- FDA 21 CFR 177.1520 (Food-contact Grades)

- UL ECVP Certified Flame-retardant Options

7. Packaging & Logistics

Standard Packaging:

- Waterproof PE Wrap + Desiccant

- Steel-reinforced Wooden Pallet

- Optional RFID Tracking Labels

Special Handling:

✓ Climate-controlled Containers (For Binder-treated Fabrics)

✓ JIT Delivery Program (±48hr Window)

FAQ

Q: How to calculate fabric requirements for conversion?

A: Use our formula:

(Target wipe size × GSM) / 1,000,000 = KG per wipe

Q: Shelf life of raw material rolls?

A: 18 months in dry storage (<30% RH, 15-25°C)

Q: Lead time for custom fiber blends?

A: 4-6 weeks with 30% deposit

Joa –

Very good factory, fast delivery, quality has been very stable, Betty’s service is very good, we will always cooperate with you.