When sourcing desiccants for moisture protection, most buyers focus on absorption capacity and application — but overlook an equally important factor: the packaging material. The outer pouch of a desiccant determines its moisture permeability, strength, leakage resistance, and compliance with industry standards.

This guide explains common desiccant types and which packaging materials they use, so you can make the right choice for your products and shipping conditions.

1. Main Types of Desiccants

1.1 Silica Gel

- Material: Silicon dioxide (SiO₂)

- Features: Non-toxic, chemically stable, reusable by heating

- Best for: Food, electronics, pharmaceuticals

- Absorption rate: ~25–40% of its own weight

1.2 Montmorillonite Clay

- Material: Natural bentonite clay

- Features: Low cost, eco-friendly, fast moisture absorption

- Best for: Shoes, leather goods, machinery storage

- Limitations: Less effective in high humidity

1.3 Molecular Sieve

- Material: Synthetic zeolite

- Features: Extremely fast moisture uptake, works well in low humidity (low dew point)

- Best for: Precision instruments, medical devices

1.4 Calcium Chloride

- Material: CaCl₂ salt

- Features: High absorption capacity (up to several times its weight), but turns into liquid after absorbing moisture

- Best for: Container shipping, long-term storage

- Special Note: Requires leak-proof packaging

1.5 Activated Alumina

- Material: Aluminum oxide (Al₂O₃)

- Features: Heat-resistant, stable absorption

- Best for: Gas and liquid drying, industrial systems

1.6 Quicklime

- Material: Calcium oxide (CaO)

- Features: High absorption, generates heat upon reaction with water

- Best for: Industrial and mechanical protection (non-food)

1.7 Composite Desiccants

- Material: Mixed formulation (e.g., silica gel + calcium chloride)

- Features: Balanced cost and performance

- Best for: Logistics, storage, export packaging

2. Common Desiccant Packaging Materials

2.1 Paper Bag

Advantages: Good breathability, low cost, widely available.

Limitations: Lower tear resistance, not suitable for liquid-forming desiccants.

Used for: Silica gel, clay, activated alumina.

2.2 Nonwoven Fabric Bag

Advantages: Strong, durable, good moisture permeability, resists tearing.

Limitations: Slightly higher cost than paper.

Used for: Silica gel, clay, molecular sieve, composite types.

2.3 Tyvek®

Advantages: Dust-free, medical-grade, excellent permeability with barrier properties.

Limitations: Higher cost.

Used for: Pharmaceutical silica gel, molecular sieve.

2.4 Laminated Film

Advantages: Combines moisture permeability with structural strength.

Limitations: Not as breathable as pure nonwoven.

Used for: Molecular sieve, composite desiccants for electronics.

2.5 Leak-proof Nonwoven

Advantages: Prevents liquid leakage, still breathable.

Limitations: Heavier and bulkier.

Used for: Calcium chloride, high-absorption composites.

2.6 Plastic Shell with Permeable Cover

Advantages: Very strong, suitable for fixed installations.

Limitations: Less flexible in size.

Used for: Container desiccants, air-conditioning systems.

3. Choosing the Right Desiccant & Packaging Combination

| Desiccant Type | Best Packaging Material | Pros | Cons | Buyer Tip |

|---|---|---|---|---|

| Silica Gel | Paper, Nonwoven, Tyvek® | Non-toxic, reusable, stable performance | Medium absorption capacity | For food-grade use, choose Tyvek® or FDA-certified paper. |

| Montmorillonite Clay | Paper, Nonwoven | Low cost, eco-friendly, fast moisture uptake | Less effective in high humidity | Ideal for cost-sensitive and short-term storage. |

| Molecular Sieve | Nonwoven, Tyvek®, Laminated | Very fast absorption, works in low humidity, high-temperature resistance | Higher price | Best for precision electronics and medical devices. |

| Calcium Chloride | Leak-proof Nonwoven, Plastic | Extremely high absorption, effective for long-term shipping | Turns to liquid, needs leak-proof packaging | Always use in sealed containers for sea freight. |

| Activated Alumina | Paper, Nonwoven | Heat-resistant, stable performance, reusable | Higher cost than clay or silica gel | Suitable for gas drying and high-temperature storage. |

| Quicklime | Paper (industrial use) | Very high absorption, low cost | Generates heat, not food-safe | Use only for industrial or mechanical protection. |

| Composite | Nonwoven, Laminated, Leak-proof | Balanced performance, adaptable to different climates | Price varies depending on mix | Great choice for export shipping and mixed cargo. |

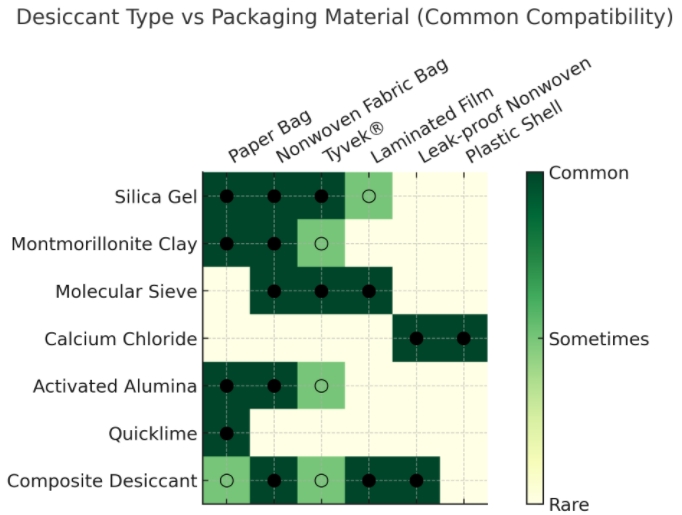

4. Desiccant & Packaging Compatibility Matrix

5. Key Takeaways for Buyers

- Match desiccant type to your product’s moisture sensitivity.

- Packaging is not universal — paper, desiccant nonwoven, Tyvek®, laminated film, and leak-proof bags serve different purposes.

- For container shipping, always use leak-proof solutions (especially with calcium chloride).

- For medical or food packaging, prioritize dust-free, certified materials like Tyvek®.

- Always check regulatory compliance (FDA, REACH, RoHS) before purchasing.

Conclusion: Understanding both the desiccant type and its packaging material is essential for making the right purchase. The right match ensures maximum moisture protection, prevents product damage, and meets industry regulations.