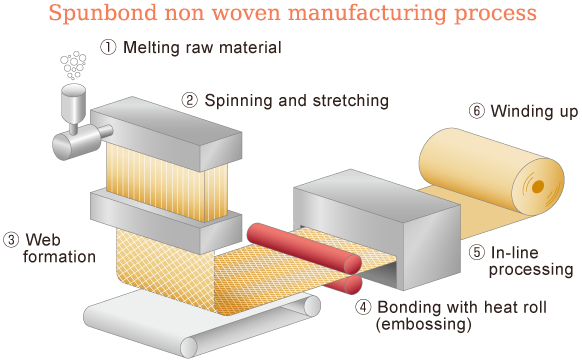

Spunbond nonwovens are a type of nonwoven fabric made from polymers such as polypropylene, polyethylene, and polyester. The spunbond nonwoven process involves melting the polymer, extruding it through a spinneret, and then cooling and stretching the filaments to form a continuous web. The web is then bonded together by thermal, chemical, or mechanical means.

The spun bond process of making spunbond nonwoven fabric begins with the melting of the polymer. The process is known for being efficient and allowing high-speed production.

Here’s a more detailed breakdown of the spunbond manufacturing process:

- Polymer Preparation

- The spunbond production process begins with the selection of polymer granules, such as polyester, polypropylene, or other thermoplastic materials.

- The polymer granules are fed into an extruder, where they are heated and melted into a viscous, molten state.

- The spunbond production process begins with the selection of polymer granules, such as polyester, polypropylene, or other thermoplastic materials.

- Stretching and Spinning

- The molten polymer is pushed through a device called a spinneret, which has multiple tiny holes or nozzles.

- As the polymer is forced through the spinneret, it forms long, continuous filaments. These filaments are immediately cooled using a cooling air stream.

- The filaments are stretched to increase their strength through a process known as drawing or attenuation. This stretching also aligns the polymer chains, which further enhances the strength and durability of the resulting fabric.

- The molten polymer is pushed through a device called a spinneret, which has multiple tiny holes or nozzles.

- Web Formation

- After spinning and drawing, the continuous filaments are laid down randomly onto a moving conveyor belt to form a web.

- The web is spread evenly over the conveyor belt, with the filaments interlocking naturally due to their random arrangement. This web formation process can be adjusted to control the thickness and density of the resulting nonwoven fabric.

- At this stage, the fabric still lacks cohesion and must undergo bonding to gain strength and stability.

- After spinning and drawing, the continuous filaments are laid down randomly onto a moving conveyor belt to form a web.

- Bonding

- The web is then bonded using one of several methods, depending on the desired properties of the final fabric:

- Thermal Bonding: The most common method, where the web is passed through heated rollers (called calender rollers). The heat partially melts the filaments, causing them to fuse together at their contact points. The calender rollers can be smooth or patterned to impart different surface characteristics to the fabric.

- Ultrasonic Bonding: Uses high-frequency vibrations to generate heat, which melts and bonds the filaments at localized points. This method is often used for bonding specific areas without applying heat across the entire web.

- Chemical Bonding: In some cases, a chemical binder is applied to the web before passing it through a curing oven, where heat activates the binder and bonds the fibers together.

- Mechanical Bonding: This can include needle-punching or hydroentangling, where high-pressure water jets are used to entangle the fibers physically. However, this method is less common for spunbond and more typical for other nonwoven types.

- Thermal Bonding: The most common method, where the web is passed through heated rollers (called calender rollers). The heat partially melts the filaments, causing them to fuse together at their contact points. The calender rollers can be smooth or patterned to impart different surface characteristics to the fabric.

- The web is then bonded using one of several methods, depending on the desired properties of the final fabric:

- Finishing and Winding

- After bonding, the nonwoven fabric may undergo various finishing treatments to improve or customize its properties. These treatments may include:

- Surface Treatment: To make the fabric hydrophobic, hydrophilic, flame-retardant, or UV-resistant.

- Printing: To add patterns, colors, or branding.

- Cutting and Slitting: The fabric is cut to the desired width and length, depending on the application.

- Surface Treatment: To make the fabric hydrophobic, hydrophilic, flame-retardant, or UV-resistant.

- The finished nonwoven fabric is then wound onto rolls for easy storage, transportation, and further processing.

- After bonding, the nonwoven fabric may undergo various finishing treatments to improve or customize its properties. These treatments may include:

- Quality Control

- During the entire spunbond manufacturing process, quality control is essential to ensure consistency and performance of the final fabric.

- Tests are conducted to check the fabric’s weight, tensile strength, elongation, air permeability, and other specifications to meet industry standards.

- During the entire spunbond manufacturing process, quality control is essential to ensure consistency and performance of the final fabric.

Advantages of the Spunbond Process

- High Production Speed: The continuous nature of the process allows for rapid production, making it cost-effective.

- Uniformity: The process ensures consistent distribution of fibers, resulting in a uniform fabric with predictable properties.

- Customization: Different bonding methods and finishing treatments allow manufacturers to tailor the fabric to specific needs, making spunbond nonwoven fabric versatile for many applications.

The spunbond process is valued for its efficiency and flexibility, which enables the production of nonwoven fabrics with specific properties and applications across a variety of industries, such as medical, automotive, agriculture, and construction.If you’re have any question about the spunbond manufacturing process or looking for spunbond non woven fabric manufacturer, please contact us.