Spunlace nonwovens are made by a process called hydroentanglement. This process uses high-pressure jets of water to entangle fibers together, creating a strong, durable fabric. The process begins with a web of fibers, which can be natural or synthetic, laid out on a conveyor belt.

The web is then passed through a series of jets that spray water at high pressure onto the fibers. The water jets cause the fibers to tangle and interlock, forming a strong bond between them. The web is then dried and finished to create the desired product.

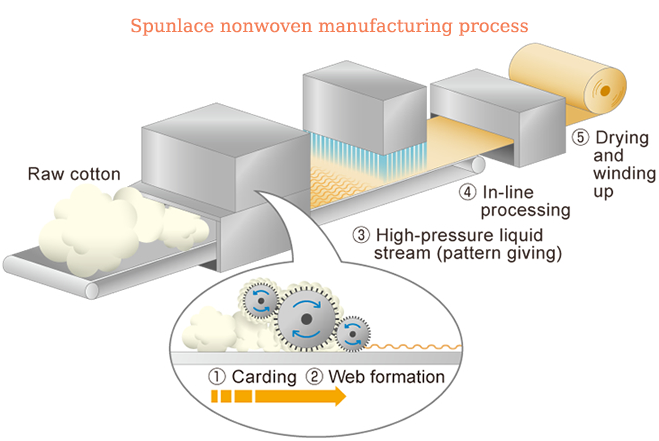

Spunlace-type of nonwoven fabric is processed as follows:

Step 1: Organize fibers by carding.

Step 2: Form a drylaid web.

Step 3: Staple fibers are entangled together by high-pressure liquid stream, and form a nonwoven fabric.

Step 4: Perform special in-line processing.

Step 5: Dry and wind up the sheet.

Hello,

Is drying compulsory before winding ? And if yes how is the drying of the spunlace done ? With hot air and infrared heating ?

Yes,Hot air drying is a common method employed for drying spunlace nonwoven fabrics.