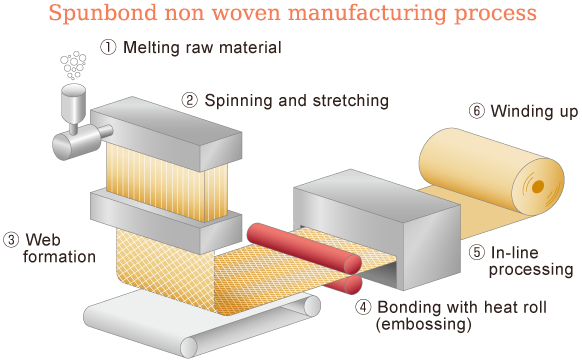

Spunbond nonwovens are a type of nonwoven fabric made from polymers such as polypropylene, polyethylene, and polyester. The process of making spunbond nonwovens involves melting the polymer, extruding it through a spinneret, and then cooling and stretching the filaments to form a continuous web. The web is then bonded together by thermal, chemical, or mechanical means.

The process of making spunbond nonwovens begins with the melting of the polymer. The polymer is melted in an extruder, which is a machine that melts and pumps the molten polymer through a spinneret. The spinneret is a device with many small holes that the molten polymer is forced through. The molten polymer is then cooled and stretched to form filaments.

The filaments are then collected on a conveyor belt and transported to a bonding area. In the bonding area, the filaments are bonded together by thermal, chemical, or mechanical means. Thermal bonding is the most common method used in the production of spunbond nonwoven fabric. In this process, the filaments are heated to a temperature that causes them to melt and fuse together. Chemical bonding is also used, in which a chemical adhesive is applied to the filaments to bond them together. Mechanical bonding is the least common method, in which the filaments are mechanically interlocked to form a web.

Once the filaments are bonded together, the web is then passed through a series of rollers to form a continuous sheet. The sheet is then cut into the desired width and length. The sheet is then wound onto a roll and packaged for shipment.

Spunbond nonwovens are used in a variety of applications, including medical products, filtration media, and protective apparel. They are lightweight, strong, and breathable, making them ideal for a variety of uses. The process of making spunbond non-woven fabric is relatively simple and cost-effective, making it a popular choice for many non woven material manufacturers.