The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments, integrated with the conversion of the filaments into a random laid nonwoven fabric. First developments in this field of technology in the industrial area started around 1945.

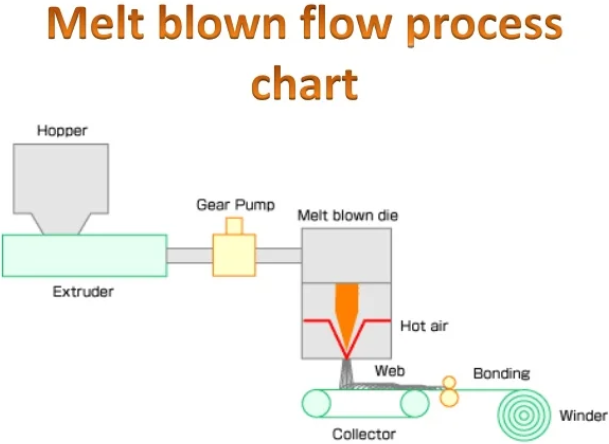

The general process description is similar to the spunlaid process, but in detail, both types of processes are quite different. Using the melt blown technology, the spun filaments are accelerated by means of hot, fast-flowing air that is directly blown onto a moving substrate, creating a self-bonded web.

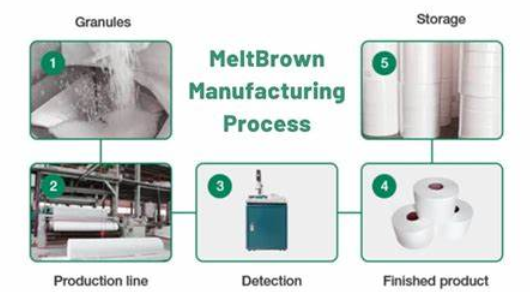

The melt blown nonwoven manufacturing process mainly includes the following steps:

1. Polymer preparation: The polymer is melted and extruded into a hopper.

2. Meltblown die: The polymer is extruded through a die to form a thin stream of molten polymer.

3. Air supply: High-pressure air is supplied to the die to create a turbulent air stream.

4. Fiber formation: The molten polymer is drawn into the air stream and broken into fine fibers.

5. Fiber collection: The fibers are collected on a moving belt and cooled.

6. Web formation: The fibers are bonded together to form a nonwoven web.

7. Finishing: The web is finished with additional treatments such as calendaring, embossing, and lamination.