Needle punch non-woven fabric production line is one kind of methods for producing nonwoven fabrics. In the process of producing, instead of using the traditional weaving process of the fabrics, the needle punch bond method uses triangle needles averagely punching in the cotton web to make the fibers directly tangle each other together; controlling the density, intensity, and function of the fabrics by needle density, needle depth, needle number, and other physical elements. No water, air, heat and chemicals are needed at all.

It is a kind of pure physical and mechanical bonding method, saving energy and non-pollution. Finished products maintain 100% yield form ram materials. It is the best green products for environmental protection. And finally it still can be 100% recycled by physical disposal, and can be reused.

The needle punched nonwoven manufacturing process mainly includes the following steps:

1. Fiber Preparation: The first step in the needle punched nonwoven manufacturing process is to prepare the fibers that will be used to create the fabric. This can involve blending different types of fibers together, or simply separating them into individual strands.

2. Web Formation: The fibers are then laid out in a web formation, which is a pattern of fibers that will be used to create the fabric. This web formation is usually done by a machine, such as a carding machine, which will comb the fibers into the desired pattern.

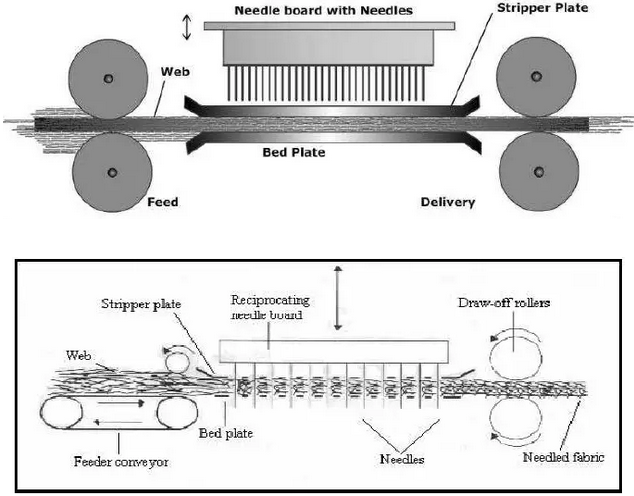

3. Needle Punching: Once the web formation is complete, the fibers are then punched with needles. This process helps to interlock the fibers and create a stronger fabric.

4. Finishing: After the needle punching process is complete, the fabric is then finished. This can involve adding a backing, such as a scrim, or adding a coating to the fabric to make it more durable.