Description

Jute felt is a purely natural material made from the fibers of subtropical jute plants, which is characterized by excellent mulching and insulating capabilities. Growers use jute felt as protective covers for plant roots or tree trunks.

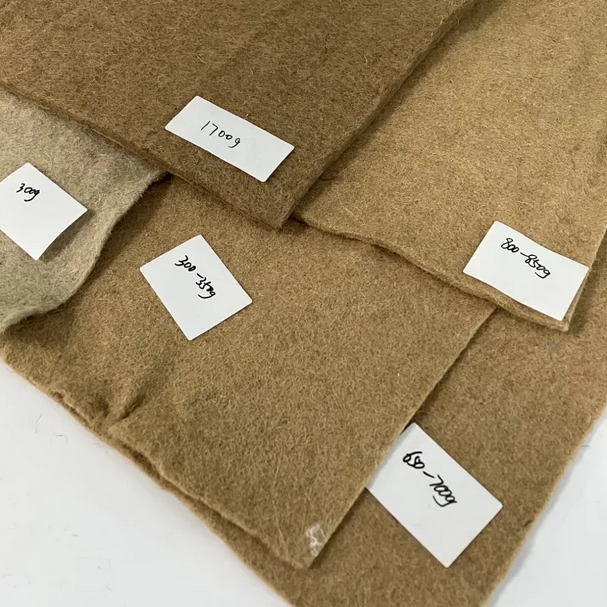

As a leading jute felt manufacturer since 2010, NW Fabric delivers OEKO-TEX® certified natural fiber solutions engineered for industrial durability and eco-compliance. Our ISO 9001:2015 certified production ensures precise thickness (2mm-12mm) and density (200-1800gsm) control across bulk orders.

Technical Specifications

| Parameter | Specifications |

|---|---|

| Material Composition | 100% Raw Jute Fibers |

| Thickness Range | 2mm – 12mm (±0.2mm tolerance) |

| Density Options | 200gsm – 1800gsm |

| Standard Sizes | Rolls: 1m/1.5m/2m width x 50m |

| Sheets: Custom-cut up to 5m x 3m | |

| Fire Rating | BS 5852 / EN 1021 compliant |

| Moisture Content | <12% (ISO 2066 standard) |

6 Competitive Advantages for Industrial Buyers

-

Carbon-Neutral Production

Biodegradable manufacturing process with 72% lower CO₂ emissions vs synthetic felts (verified by SGS Life Cycle Assessment). -

Precision Engineering

Laser-calibrated needle-punching technology ensures ≤0.15mm thickness variance across production batches. -

Multi-Industry Compliance

Certified for:

-

Automotive (ISO/TS 16949)

-

Construction (EN 13501-1 Class B-s2,d0)

-

Child-Safe Products (EN71-3:2019)

-

Customizable Solutions

-

Die-cutting services with ±1mm precision

-

Custom blending with wool/bamboo fibers

-

Branded packaging & palletization

-

Global Logistics Network

FCA/FOB terms with 15-22 day lead time to EU/US ports. MOQ from 500kg. -

Technical Support

Free material testing reports + CAD files for prototyping available.

Industrial Applications

Automotive Sector

-

Dashboard insulation pads (meets SAE J369 flame retardancy)

-

Battery separator layers for EVs

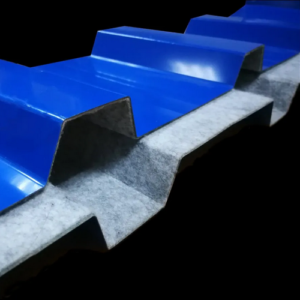

Construction Solutions

-

Acoustic wall panels (NRC 0.65-0.85 tested per ASTM C423)

-

Green roof root barriers

Consumer Manufacturing

-

Luxury packaging inserts

-

Eco-friendly furniture padding

Agricultural Applications

Hydroponic Systems

-

Microgreen Production: 10-layer vertical farming stacks

-

Wheatgrass Trays: Non-slip base for juice bar operations

-

Sprout Cultivation: Roll-based continuous harvest systems

Soil-Based Farming

-

Seedling nursery bed liners

-

Biodegradable weed control mats

-

Erosion control blankets for sloped fields

Post-Harvest Solutions

-

Organic produce cushioning pads

-

Compostable packaging inserts

Certified Quality Assurance

-

Raw Material Testing: SGS ID 402.1 (heavy metal free)

-

Production Standards: ISO 9001:2015 + WRAP

-

Every batch includes:

-

Thickness distribution map

-

Tensile strength report (≥18N/cm² warp/weft)

-

pH value certification (6.5-7.8 range)

-

FAQ

Q: What’s the MOQ for custom jute felt orders?

A: Standard MOQ 500kg, with prototype samples available from 5kg.

Q: Do you provide REACH compliance documentation?

A: Yes, full SDS and SVHC statements accompany all EU-bound shipments.

Q: How does jute felt compare to synthetic alternatives?

A: 38% lighter than polyester felt with comparable tensile strength (per ASTM D5035 testing).

Rustin –

Quailty is overall good for material/price. The color, look and smell is as expected. My beetroot seeds germinated quickly. The micro greens did not have a strange taste they were good. These are messy to unpackage but I expected that too.