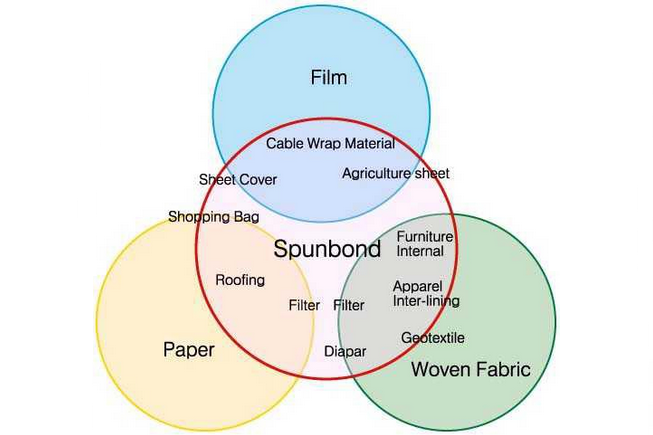

In the recent past spun bond nonwovens have developed rapidly due to their excellent properties and high process efficiency. Presently it occupies the largest share among the various techniques of nonwoven fabric manufacture and finds application in different fields.

Nonwoven products made by using the spunbond nonwoven process are variously used in disposable and medical applications, automotive industry, filtration, civil engineering, packaging applications, carpet backing applications, geotextiles, durable papers, bedding, pillows, furnishings, and others.

The spunbond process has been used for diapers and incontinence products. It has been used in medical applications such as disposable operating room gowns, shoe covers and sterilization packaging, because it has the particular properties including breath ability, resistance to fluid penetration, sterilizability, and impermeability to bacteria.

In automotive industry, the spunbond webs are used for tufted automobile floor carpets, for trim parts, trunk liners, interior door panel, and seat covers.

In filtration industry, the spunbond webs are used in various applications including pool and spa, air particulate, coolant, milk and sediment for household water.

In civil engineering, they are used in erosion control, revetment protection, railroad bed stabilization, canal and reservoir lining protection, highway and airfield black top cracking prevention, and roofing, because it has the particular properties including chemical and physical stability, high strength, and their highly controllable structure properties.

CONCLUSION

Nonwoven fabrics made by spunbond nonwoven process are being used in various applications like most of time that nonwoven is used for preparation of bags. The consumption of spun bond fabrics in durable and disposable products is continuously growing and the development of new products with hydro entanglement of spun bonds is expected to further increase the market. Many nonwoven companies have engaged in spun bond nonwoven technology around the world. In the future spun bond products will continue to rapidly increase market share and penetrate new markets including some portions of the apparel market.