Condensation on metal roofs is a persistent challenge for steel structure owners, manufacturers, and construction professionals. Left unaddressed, dripping condensation can damage insulation, corrode roof sheets, and compromise indoor air quality. Fortunately, modern engineering and innovative materials like anti condensation felt offer reliable solutions. Below, we break down six actionable strategies to combat condensation in metal buildings, tailored for metal roofing manufacturers and anti-condensation product buyers.

1. Control Moisture at the Source

Moisture accumulation is the root cause of condensation. For steel roof sheets, this often stems from internal humidity from HVAC systems, industrial processes, or human activity. To mitigate this:

- Monitor indoor humidity levels using hygrometers and aim to keep relative humidity below 60%.

- Install vapor barriers beneath the roof to block moisture rising from indoor spaces.

- Seal gaps around doors, windows, and vents to prevent humid outdoor air from entering.

For manufacturers, integrating vapor-resistant coatings into metal roofing sheets can add an extra layer of protection.

2. Optimize Ventilation Systems

Proper ventilation balances temperature and humidity differences between indoor and outdoor environments. Two approaches work synergistically:

- Natural ventilation: Design ridge vents, soffits, or louvers to allow continuous airflow.

- Mechanical ventilation: Use exhaust fans or HVAC systems in high-humidity areas like warehouses or agricultural facilities.

Roofing manufacturers should prioritize designs that accommodate ventilation components, such as pre-cut vent slots or modular panels.

3. Install Correct Insulation

Insulation acts as a thermal buffer, reducing the temperature differential that drives condensation. Key considerations:

- Choose closed-cell spray foam or rigid foam boards with high R-values to minimize heat transfer.

- Ensure insulation is installed tightly against the roof deck without gaps to prevent cold spots.

- Pair insulation with a radiant barrier to reflect heat and further stabilize surface temperatures.

For buyers, verify insulation compatibility with anti-condensation products like NW Fabric’s felt to ensure cohesive performance.

4. Choose the Right Roof Pitch and Corrugation Design

A roof’s slope and profile impact how quickly moisture evaporates or drains:

- Minimum pitch: A slope of 1:12 (4.8°) or steeper encourages water runoff.

- Deep-corrugated panels: Channels in the metal sheets direct condensation away from the roof surface.

- Anti-sag design: Reinforced ribs prevent pooling water, which exacerbates condensation risks.

Manufacturers can reduce condensation complaints by pre-engineering roof systems with these features.

5. Invest in Dehumidifiers for High-Risk Environments

In spaces like cold storage units or swimming pool enclosures, dehumidifiers provide active moisture control:

- Desiccant dehumidifiers excel in low-temperature environments.

- Size units appropriately based on room volume and humidity load.

- Integrate systems with smart sensors to automate operation and reduce energy costs.

While not a standalone fix, dehumidifiers complement passive solutions like anti-condensation membranes.

6. Deploy Anti-Condensation Felt: The Ultimate Safeguard

Traditional solutions often fall short in extreme climates or high-moisture settings. This is where NW Fabric’s anti-condensation felt shines.

What Is Anti-Condensation Felt?

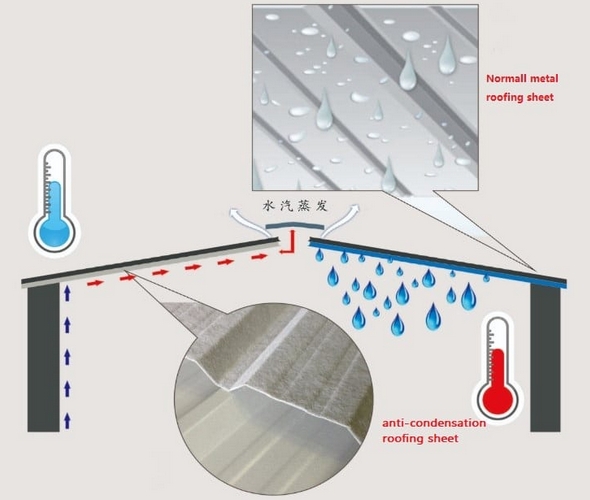

Anti-condensation felt is a high-performance membrane engineered to combat condensation on metal surfaces such as steel roofs and wall panels. Made from polyester needle punched non-woven fabric, this specialized material addresses the persistent issue of moisture droplets forming when warm, humid indoor air meets colder metal surfaces. Left unchecked, condensation can lead to dripping water, mold growth, insulation degradation, and structural corrosion.

Self adhesive anti condensation fleece is engineered to tackle condensation on metal roofs with precision and efficiency. Designed for seamless integration with PBR Panels and Max Panels, this advanced membrane employs a science-backed approach to moisture management.

Here’s how it works and why it outperforms traditional solutions:

How It Works: The Science of Moisture Control

- Trapping Mechanism:

The felt features a specialized membrane with engineered micro-pockets that capture condensation as it forms on the underside of metal roof sheets. These pockets temporarily hold moisture, preventing it from dripping onto insulation, equipment, or inventory below. - Dynamic Release:

The trapped moisture is retained until the relative humidity in the environment drops below 100%. At this point, the stored water vapor is safely released back into the air, maintaining a balanced indoor climate without pooling or leakage. - Integrated Application:

The self-adhesive backing allows the felt to be applied directly to metal panels during the roll-forming process. This ensures a flawless bond with the steel surface, eliminating gaps or air pockets that could compromise performance.

Key Applications

Anti-condensation felt is widely used in:

- Metal roofing systems (e.g., PBR panels, Max Panels, agricultural buildings, warehouses).

- Cold storage facilities with extreme temperature fluctuations.

- High-humidity environments like factories, swimming pools, and livestock barns.