Polypropylene (PP) is a superstar in the plastics world, especially for nonwoven fabrics. From medical gowns and shopping bags to filters and geotextiles, its durability, versatility, and cost-effectiveness are unmatched. But in our sustainability-focused era, a critical question shadows its success: Is polypropylene biodegradable?

The Fundamental Answer: Traditional PP is NOT Biodegradable.

Let’s be clear first: Standard, virgin polypropylene, as traditionally manufactured and used, is NOT biodegradable in natural environments. Here’s why its persistence is a scientific fact:

- Chemical Fortress: PP is built on long, stable chains of carbon and hydrogen atoms linked by incredibly strong covalent bonds. Microbes lack the enzymes to break these bonds effectively.

- Tightly Packed: Its often crystalline structure makes it dense and impenetrable to microbial attack.

- Water-Repellent: Being hydrophobic, PP doesn’t attract the moisture microbes need to thrive and decompose materials.

- Alien to Nature: Microbes haven’t evolved to recognize synthetic PP as a food source over the millennia.

The Evidence of Persistence:

- Landfills & Oceans: Traditional PP items can persist for decades or even centuries, fragmenting into microplastics but not truly biodegrading.

- Scientific Consensus: Rigorous lab and field tests consistently show negligible microbial breakdown of standard PP within meaningful timeframes under natural conditions (soil, seawater, ambient compost).

Fragmentation is NOT Biodegradation!

When PP breaks into smaller pieces (microplastics) due to sunlight, wind, or waves, it’s degrading, not biodegrading. The plastic pollution problem changes form but persists, posing ecological and health risks.

The Game Changer: Emerging Biodegradable PP Options

Here’s where the story gets more nuanced and hopeful, particularly for the nonwoven industry:

Driven by environmental demands, innovative manufacturers and material scientists are developing biodegradable PP materials designed to be biodegradable. These are distinct from traditional PP and represent a significant advancement:

- The Technology: These materials typically involve adding specific organic or pro-degradant additives during the PP manufacturing process. These additives act in different ways:

- Catalyzing Oxidation: Some additives accelerate the polymer’s reaction with oxygen and UV light, breaking the long chains into smaller, lower molecular weight fragments first.

- Providing Microbial “Food”: Other additives incorporate bio-based components (like starches or fatty acid esters) that microbes can consume. As microbes digest these components, they physically weaken the plastic structure, potentially allowing access to the fragmented PP chains.

- The Result: This combination of oxo-degradation followed by potential bio-assimilation aims to significantly accelerate the breakdown process compared to traditional PP, ideally leading to complete mineralization (conversion to CO2, water, biomass) under the right conditions.

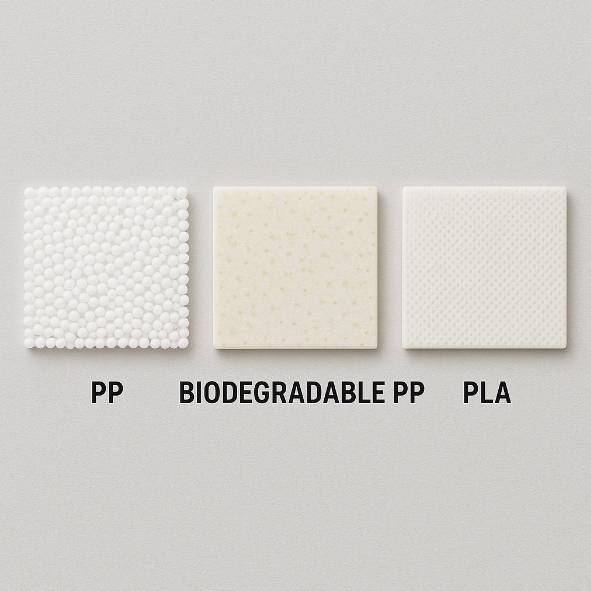

- Key Distinction from PLA: While PLA is a bio-based polymer designed to be biodegradable from the outset, these modified PPs are still fundamentally fossil-fuel based polypropylene that has been engineered to become biodegradable after an initial abiotic degradation phase. They leverage existing PP production infrastructure but add functionality.

Crucial Considerations for Biodegradable PP:

- Condition Dependency: Biodegradation of these modified PPs is highly dependent on specific environmental conditions:

- Requires Oxygen: The initial oxidative fragmentation step requires oxygen (aerobic conditions).

- Microbial Activity: Subsequent biodegradation needs sufficient microbial populations and activity, influenced by temperature, moisture, and nutrient availability.

- Timeframe: While faster than traditional PP, degradation still takes months to years and is generally slower than materials like PLA in industrial composters.

- Standards & Certifications: Look for materials certified to relevant standards (e.g., ASTM D6954 for “Oxo-biodegradation,” or potentially newer standards emerging for PP biodegradability). Always verify claims with specific test data and certifications. “Biodegradable” is not enough – ask where and how fast under which conditions.

- End-of-Life Management: For optimal breakdown, these materials often require industrial composting facilities (which provide controlled heat, moisture, and aeration). Performance in home compost, soil, or marine environments is typically much slower or negligible. They are NOT designed for conventional plastic recycling streams and can contaminate them.

Sustainable Pathways for PP: Beyond (or Including) Biodegradability

Whether using traditional PP or exploring biodegradable versions, responsible lifecycle management is key:

- Mechanical Recycling (Priority for Traditional PP): PP (#5) is highly recyclable. Robust collection, sorting, and processing are vital to turn used nonwovens and other PP products into recycled PP (rPP) pellets. Support rPP demand!

- Advanced/Chemical Recycling: Technologies like pyrolysis offer promise for complex or contaminated PP waste, breaking it back down to feedstock. Scaling is ongoing.

- Reduction & Reuse: Minimize unnecessary use. Design durable reusable nonwoven products (e.g., shopping bags, cleaning cloths).

- Biodegradable PP (Strategic Use): For applications where collection and recycling are highly impractical (e.g., specific agricultural mulch, certain hygiene products where industrial composting exists), certified biodegradable PP can be a responsible niche solution. Choose based on verifiable certifications and realistic end-of-life pathways.

- Proper Disposal: Ensure PP waste enters the correct stream (recycling for traditional PP, organics/composting only if certified for that pathway and the facility accepts it).

Comparing the Options: Traditional PP, Biodegradable PP & PLA

| Feature | Traditional PP | Biodegradable PP (Modified) | PLA (Bioplastic) |

|---|---|---|---|

| Base Material | Fossil Fuels | Fossil Fuels (with Additives) | Renewable (e.g., Corn, Sugarcane) |

| Biodegradable? | NO (Persistent) | YES (Condition-Dependent) | YES (Condition-Dependent) |

| Primary Mechanism | N/A | Oxo-degradation + Bio-assimilation | Direct Microbial Assimilation |

| Key Conditions | N/A | Needs Oxygen, Microbes, Time; Best in Industrial Compost | Needs Industrial Compost (High Heat/Humidity) |

| Home Compost? | No | Typically No or Very Slow | No |

| Recyclable? | Yes (Mechanical – #5) | Generally NO (Contaminant) | Requires Specialized Streams |

| Compostable? | No | Often Industrially Compostable (Check Cert!) | Industrially Compostable |

| Key Advantage | Durability, Cost, Recyclability | Potential End-of-Life Breakdown where Recycling Fails | Renewable Source, Compostability |

| Key Challenge | Persistence, Microplastics | Needs Specific Conditions; Recycling Contamination | Limited End-of-Life Options; Performance |

Conclusion: Knowledge is Power for Sustainable Choices

Traditional polypropylene remains non-biodegradable, making recycling and reduction essential. However, the development of engineered biodegradable PP materials marks a significant innovation, particularly for the nonwoven sector, offering potential end-of-life solutions for hard-to-recycle applications under controlled conditions.

The Key Takeaways:

- “Biodegradable” is NOT automatic: Scrutinize claims for any plastic, including modified PP. Demand certifications (ASTM D6954, etc.) and understand the required conditions.

- Recycling Reigns Supreme (for now): Mechanical recycling remains the most established and circular path for the vast majority of PP waste, including nonwovens. Invest in its infrastructure.

- Biodegradable PP is Niche, Not Universal: It’s a valuable tool for specific applications where recycling isn’t feasible and proper industrial composting is guaranteed. It is NOT a license to litter.

- End-of-Life Dictates Choice: The intended disposal pathway must drive material selection. Don’t use biodegradable PP if it will end up in landfill or recycling.

By understanding the nuances of traditional PP, the potential and limitations of new biodegradable PP variants, and the clear role of PLA, businesses and consumers can make far more informed and responsible choices for a more sustainable future. The path forward involves a mix of solutions tailored to application and disposal realities.