Nonwoven fabric is a fabric-like material, also known as non-woven fabric. Nonwovens are innovative, high-tech, engineered fabrics made from fibres. They are used in a wide range of consumer and industrial products either in combination with other materials or alone.

Nonwovens are typically manufactured by putting small fibers together in the form of a sheet or web (similar to paper on a paper machine), and then binding them either mechanically (as in the case of felt, by interlocking them with serrated needles such that the inter-fiber friction results in a stronger fabric), with an adhesive, or thermally (by applying binder (in the form of powder, paste, or polymer melt) and melting the binder onto the web by increasing temperature).

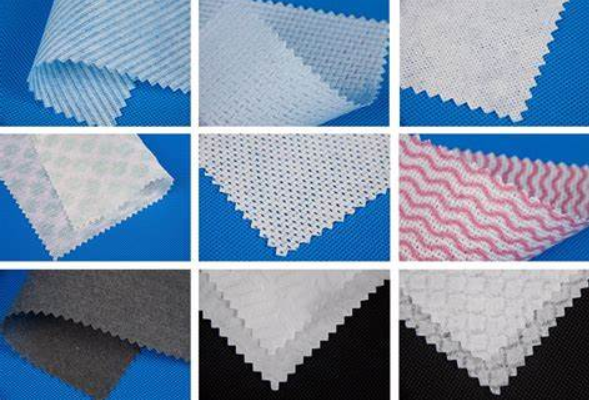

Nonwovens are designed for their specific application, ranging from thin, light weight nonwovens to strong and durable nonwovens, be it consumer or industrial applications. The combination of their specific characteristics through the raw materials selection, the formation and bonding methods used or the applied finishing treatments, such as printing, embossing, laminating etc. allow to deliver high-performance products.

Types of non-woven fabrics

1. Spunbond non woven fabric

Spun bonded non woven fabric utilizes polymers as the raw material for its formation. The process involves the polymers to go through extruder so it can get stretched to form a continuous filament which is laid into a web, followed by melting and spinning so that the randomly laid web can get inter-tangled. Finally, the fabric is formed when the web is treated either chemically, by application of heat to make the polymer melt and stick, or mechanically where pressure makes the polymer stick strongly.

2. Spunlace NonWoven Fabric

Spunlace non-woven fabric got its name from the process. The process utilizes applying high-pressure water jet to the layers of the web fibers so they can get entangled and combine into a uniform fabric. The fiber used for this process includes nylon, polyester, silk, bamboo fiber, viscose fiber, wood pulp and many others. The process reinforces the webs to some degree but they are still not as strong as many other types of non-woven fabric. Spunlace non-woven fabric is quite popular for its application in the manufacturing of face masks, disposable surgical gowns, wet wipes, filter, etc.

3.Melt-blown NonWoven Fabric

Melt blown non woven fabric is made in a complex systematic procedure where melted polymer fiber is extruded through a linear die. The die contains hundreds of tiny holes that turn the melted polymer into thin fibers. The fibers are cooled by blowing hot air, and the resulting web is collected on a collector screen where they combine to form the non-woven fabric that is fined, filtered, and self-bonded. Melt-blown non-woven fabric is usually added to spunbond non-woven fabric to make webs for SM and SMS fabrics.

4.Needle Punched Non-Woven Fabric

Needle punched non woven fabric or acupunctured non-woven fabric is another dry-type fabric which is made by reinforcing fiber into cloth by using needle punching. It has a rough texture and the fabric produced this way is quite strong.

5.Air-laid paper

Also called dustless paper, air-laid paper, and dry paper non-woven; it uses air-laid technology which opens up the wood pulp fiberboards into a state of a single fiber. Then it uses a strong flow of air to combine the wooden fiber on the web and finally reinforces the pulp on the web to form the non-woven fabric.

6.Heat Bounded Non-Woven Fabric

Heat is the main agent used in this type of non-woven fabric to bind the fiber webs together. Adhesives are added to the layers of fibrous webs which are then treated with heat that melts the adhesive and then cooled which combines the multiple layers into a single fabric-like material.

7.Stitched nonwoven fabric

Stitched nonwoven fabrics are a kind of dry-laid nonwoven fabrics. The stitching method uses a warp-knitted loop structure to couple fiber webs, yarn layers, nonwoven materials (such as plastic sheets, plastic thin metal foils, etc.) or their combination. The body is reinforced to make a nonwoven fabric.

8.Flashspun nonwoven fabric

Flashspun fabric is a nonwoven fabric formed from fine fibrillation of a film by the rapid evaporation of solvent and subsequent bonding during extrusion. A pressurised solution of, for example, HDPE or polypropylene in a solvent such as fluoroform is heated, pressurised and pumped through a hole into a chamber.

9.Fiberglass nonwoven fabric

Nonwovens can also start with films and fibrillate, serrate or vacuum-form them with patterned holes. Fiberglass nonwovens are of two basic types. Wet laid mat or “glass tissue” use wet-chopped, heavy denier fibers in the 6 to 20 micrometre diameter range.

10.Others

The nonwoven sheets or webs can be functionalized, coated or laminated in the same way as conventional textile fabrics.

Non-woven materials are used in numerous applications, including:

(1)Medical

- isolation gowns

- surgical gowns

- surgical drapes and covers

- surgical masks

- surgical scrub suits

- caps

- medical packaging: porosity allows gas sterilization

- gloves

- shoe covers

- bath wipes

- wound dressings

- drug delivery

- plasters

(2)Filters

- gasoline, oil and air – including HEPA filtration

- water, coffee, tea bags

- pharmaceutical industry

- mineral processing

- liquid cartridge and bag filters

- vacuum bags

- allergen membranes or laminates with non woven layers

(3)Geotextiles

- Nonwoven geotextile bags are much more robust than woven bags of the same thickness.

- Geocomposite drain consisting of needle-punched nonwoven filter and carrier

- geotextiles of polypropylene staple fibers each having a mass per area of 200 g/m².

- Nonwoven geotextile containers (sand bags) are used for

- soil stabilizers and roadway underlayment

- foundation stabilizers

- erosion control

- canal construction

- drainage systems

- geomembrane protection

- frost protection

- pond and canal water barriers

- sand infiltration barrier for drainage tile

- landfill liners

(4)Other

- diaperstock, feminine hygiene, and other absorbent materials

- carpet backing, primary and secondary

- composites

①marine sail laminates

②tablecover laminates

③chopped strand mat

- backing/stabilizer for machine embroidery

- packaging where porosity is needed

- Shopping bags

- insulation (fiberglass batting)

- acoustic insulation for appliances, automotive components, and wall-paneling

- pillows, cushions, mattress cores, and upholstery padding

- batting in quilts or comforters

- consumer and medical face masks

- mailing envelopes

- tarps, tenting and transportation (lumber, steel) wrapping

- disposable clothing (foot coverings, coveralls)

- weather resistant house wrap

- cleanroom wipes

- potting material for plants

- wallcovering