Spunbond and meltblown are two different types of nonwoven fabric. Do you know the difference between spunbond and meltblown process? The two important polymer-extrusion based technologies that are mainly used to convert the molten polymer into nonwoven fabrics are spunbond technology and meltblown technology.

1.Spunbond technology

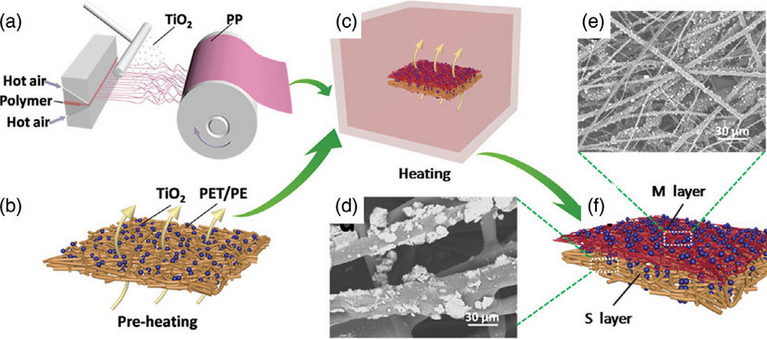

In the spunbond technology, usually a thermoplastic fibre forming polymer is extruded to form fine filaments fibres of around 15–35 micrometer diameter. The filaments are attenuated collected on a conveyor belt in the form of a web. The filaments in web are then bonded to make spunbond nonwoven fabric.

2.The meltblown technology

The meltblown technology is based on meltblowing process, where, usually, a thermoplastic fiber forming polymer is extruded through a linear die containing several hundred small orifices.

Convergent streams of hot air (exiting from the top and bottom sides of the die nosepiece) rapidly attenuate the extruded polymer streams to form extremely fine diameter fibers (1–5 micrometer). The attenuated fibers are subsequently blown by high-velocity air onto a collector conveyor, thus forming a fine fibered self-bonded meltblown nonwoven fabric.